Semi Automatic Machine

Leading Manufacturers, Exporters and Wholesaler of Semi Automatic Can Seamer Machine, Semi Automatic Cup Sealer Machine, Semi Automatic Digital Cup Sealer, Semi Automatic Lug Cap Sealing Machine, Semi Automatic Perfume Bottle Crimping Machine, Semi Automatic Perfume Filling Machine, Semi Automatic Piston Filling Machine and Semi Automatic Servo Filling Machine from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Semi Automatic Can Seamer Machine |

| Brand Name | ANASUYA |

| Voltage | 230V AC |

| Weight | 35 Kg |

| Material | SS304 Stainless Steel |

| Usage | Sealing Cans |

| Model | PCS-01 |

| Dimensions | 175mm X 240mm X 370mm |

| Power Consumption | 1000 Watts |

| Production Speed | 12-13 Cans Per Minute |

| Max Can Height | 175 Mm |

| Compatible Can Sizes | 51mm, 63mm, 80mm Diameter |

Can Seamer – Versatile & Leak-Proof Sealing Solution

Model: PCS-01 | Make: ANASUYA

Seal your cans with confidence using the ANASUYA PCS-01 Can Seamer—engineered for precision, hygiene, and efficiency. Designed to seal both PET and aluminum cans with tin lids, this compact yet powerful machine ensures a 100% leak-proof seal, ideal for packaging juices, dairy, edible oil, sauces, and more.

Whether for small production setups or commercial operations, the PCS-01 offers unmatched ease of use, quick adjustability, and professional-grade performance.

Key Features:

-

Unmatched Versatility: Compatible with multiple can diameters – 51mm, 63mm, and 80mm.

-

Leak-Proof Sealing: Delivers 100% sealing integrity for liquid-based products.

-

Induction Motor Driven: Reliable 230V AC motor ensures steady, high-performance operation.

-

Adjustable Height Mechanism: Simple lever-based adjustment to handle varying can heights.

-

Durable & Hygienic Build: Fabricated using SS304 stainless steel for easy cleaning and food-grade safety.

-

User-Friendly Design: Quick setup and intuitive operation for smooth workflow.

| Business Type | Manufacturer, Exporter, Supplier |

| Condition | New |

| Driven Type | Electric |

| Usage | Sealing Cups For Beverages Or Food Items |

| Color | Silver |

| Material | Stainless Steel |

| Type | Semi Automatic Cup Sealer Machine |

| Brand Name | ANASUYA |

| Automation Level | Semi Automatic |

| Capacity | Dia 70, 80,95,Custom Size |

| Dimensions | 650mm X 700mm X 1150mm |

| Weight | 65kgs |

Semi-Automatic Cup Sealer – Precision Meets Productivity

Model: ACS-01 | Make: ANASUYA

Streamline your cup packaging process with the ANASUYA Semi-Automatic Cup Sealer (ACS-01)—a complete solution designed for high-volume dairy, juice, and ice cream cup sealing applications. Engineered with servo-based technology, an intuitive HMI interface, and PLC control, this machine ensures accuracy, consistency, and user-friendly operation in demanding production environments.

Constructed with SS304 stainless steel, it offers excellent hygiene, durability, and low maintenance. From cup filling to foil sealing and cup ejection, this compact unit handles the essential steps of the process efficiently.

For customization or combo unit options, please contact our sales team.

Key Features:

-

Auto-Homing: Quick and easy machine setup with automatic alignment.

-

Speed Adjustment: Matches your exact production pace.

-

Non-Drip Valve: Ensures mess-free and accurate filling.

-

Foil Checking System: Confirms perfect seal placement every time.

-

No Cup – No Fill – No Seal: Reduces waste and error.

-

Brass Heater Block: Hollow brass block ensures uniform heating and strong seals.

-

Future-Ready Design: Easily upgradable for long-term scalability.

-

Flexible Integration: Connects with gear pump, piston, or gravity fillers.

-

Low Maintenance: Easy to clean and service for minimal downtime.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | ANASUYA |

| Type | Semi Automatic Digital Cup Sealer |

| Material | Mild Steel With Powder Coating |

| Color | Red,Black |

| Voltage | 230V AC |

| Power Consumption | 325 Watts |

| Production Speed | 6-8 Cups Per Minute |

| Heater Block | Hollow Brass Heater |

| Weight | 12.5 Kg |

| Supported Cup Sizes | Dia 70-80mm, 80-95mm, 70-95mm |

| Max Cup Height | 185 Mm |

Combo Cup Sealer – Dual Size Sealing, Maximum Flexibility

Model: MCS-02 COMBO | Make: ANASUYA

Achieve professional-grade sealing with the ANASUYA Combo Cup Sealer (MCS-02 COMBO), built for efficiency in fast-paced environments such as takeaway counters, juice bars, cafés, restaurants, and emerging beverage brands. Designed to seal aluminum lids on a variety of cup types—paper, plastic, PP, and HDPE—this compact machine is optimized for flexibility and performance.

The combo sealing mechanism supports dual cup diameters (e.g., 70–80mm, 80–95mm, or 70–95mm) and can adapt to any cup height up to 185mm. Switching between sizes is quick and easy with an interchangeable ring attachment.

Equipped with a thermocouple, temperature controller, and hollow brass heater, this machine ensures consistent heat distribution for a perfect seal every time.

Key Features:

-

Dual Diameter Support: Compatible with 70mm–95mm cup diameters.

-

Universal Height Adaptability: Works with cups up to 185mm tall.

-

Quick Change Mechanism: Swap ring attachments to switch sizes easily.

-

Consistent Sealing: Hollow brass heater ensures uniform heat.

-

Compact & Stylish Design: Powder-coated MS body in red or black finish.

-

Ideal for F&B Outlets: Perfect for takeaway, juice, and coffee counters.

-

Available Accessories: Aluminum lids and cups supplied on request.

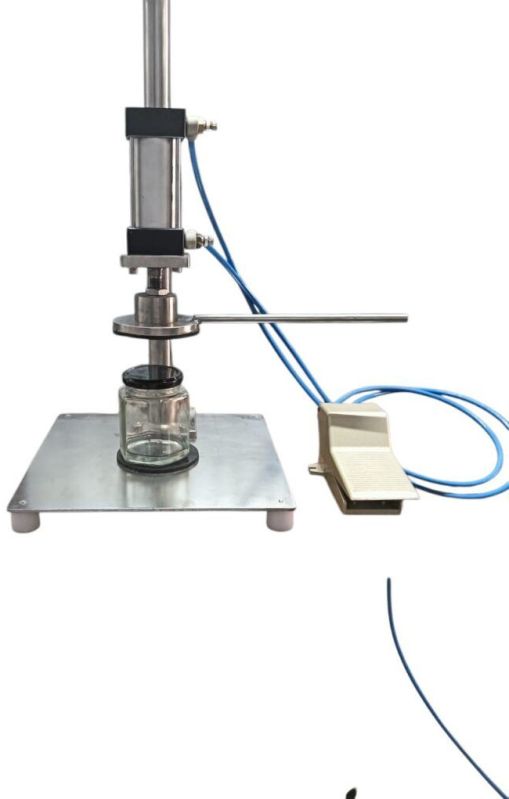

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Pneumatic |

| Brand Name | ANASUYA |

| Type | Semi Automatic Lug Cap Sealing Machine |

| Application | Jar Sealing |

| Model | LC-01 |

| Material | SS304 Stainless Steel ,Cast Iron With Powder Coating(Both are Available) |

| Power Source | Pneumatic Cylinder At 70-75 PSI |

| Dimensions | 175 Mm X 240 Mm X 370 Mm |

| Air Requirement | 70-75 PSI |

| Production Speed | 12-13 Bottles Per Minute (BPM) |

| Weight | 5.5 Kg |

| Max Bottle Height | 250 Mm |

| Lid Size Range | 51 Mm To 105 Mm (Custom Sizes Available) |

LUG SEALER Simple, Efficient, and Robust Jar Sealing

Experience the ease of secure jar sealing with our Manual Lug Sealer. This compact, table-top unit offers a reliable and effortless method to tighten lug caps on jars. Designed for environments where portability and simplicity are key, it operates without electricity and is powered by a pneumatic cylinder at 70–75 PSI.

Engineered for both durability and hygiene, the Lug Sealer is available in SS304 stainless steel or cast iron with powder coating to suit various application needs. It supports a wide range of lid sizes (from 51mm to 105mm) and can accommodate jars with a height of up to 250mm, making it a versatile solution for sealing operations.

Key Features:

-

Manual, Pneumatic Operation: No electricity required – simple and cost-effective.

-

Flexible Fabrication Options: Available in SS304 or powder-coated cast iron.

-

Wide Lid Compatibility: Suitable for lug caps from 51mm to 105mm.

-

Compact Design: Space-saving and easy to operate on any tabletop.

-

Low Maintenance: Designed for long-term, trouble-free use.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Semi Automatic Perfume Bottle Crimping Machine |

| Material | Stainless Steel (SS304) |

| Power | N/A (Pneumatic Operation) |

| Weight | 14.5 Kg |

| Usage | Sealing Perfume Bottles In Small To Medium-scale Production Environments |

| Speed Adjustment | Tailor Crimping Speed To Meet Specific Production Requirements |

| Future-Ready Design | Easily Upgradable For Future Enhancements |

| Seamless Integration | Can Be Connected With Gear Pump, Piston Filler, Gravity Filler, And Vacuum Filler |

| Low Maintenance | Easy To Clean, Reducing Downtime And Improving Productivity |

| Dimensions | 200 Mm X 300 Mm X 450 Mm |

| Air Requirement | 75 PSI |

| Production Speed | 12-14 Cycles Per Minute (CPM) |

| Collet Sizes Available | 15, 16, 20, 22, 26 Mm |

| Max Bottle Height | 120 Mm (Customizable On Request) |

SEMI AUTOMATIC CRIMPER Efficient and Precise Perfume Bottle Crimping

\\n

Our Semi Automatic Perfume Crimper is the perfect solution for reliably sealing perfume bottles in small to medium-scale production environments. This pneumatically operated unit ensures consistent and accurate crimping with each use. It comes with interchangeable collets to fit various bottle sizes, offering flexibility for different packaging needs.

\\n

The compact, table-top design is ideal for quick setup and smooth operation in limited space. Equipped with a foot switch, it enables hands-free operation for better handling and increased efficiency.

\\n

Key Features:

\\n

- \\n

- \\n

Speed Adjustment: Tailor crimping speed to meet your specific production requirements.

\\n

\\n

- \\n

Future-Ready Design: Easily upgradable to accommodate future enhancements.

\\n

\\n

- \\n

Seamless Integration: Can be connected with gear pump, piston filler, gravity filler, and vacuum filler.

\\n

\\n

- \\n

Low Maintenance: Easy to clean, reducing downtime and improving overall productivity.

\\n

\\n

\\n

Boost your productivity with a reliable, precise, and easy-to-use crimping solution.

\\n

\\n

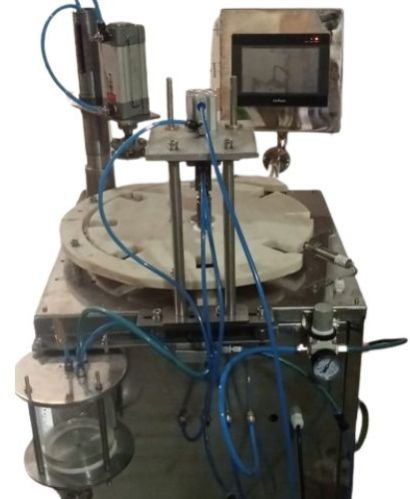

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | ANASUYA |

| Type | Semi Automatic Perfume Filling Machine |

| Material | Stainless Steel (SS304) |

| Voltage | 230V AC |

| Usage | Perfume Filling |

| Production Speed | 12-14 Bottles Per Minute |

| Model | APC-01 |

| Dimensions | 650mm X 700mm X 1150mm |

| Power Consumption | 750 Watts |

| Air Pressure Required | 75 PSI |

| Weight | 65 Kg |

| Supported Bottle Sizes | Dia 70mm, 80mm, 95mm, Custom Sizes |

| Max Bottle Height | 120mm (customizable) |

| Filling Methods | Piston Fill, Vacuum Fill, Gear Pump |

Semi-Automatic Perfume Filler – Precision Filling for High-Volume Production

Model: APC-01 | Make: ANASUYA

The ANASUYA APC-01 Semi-Automatic Perfume Filler is engineered for high-precision perfume bottle filling—perfect for small to mid-scale manufacturing. Built with servo-driven technology, a user-friendly HMI interface, and PLC control, this machine delivers consistent performance while offering ease of use and efficient output.

Constructed using SS304 stainless steel, this machine ensures hygiene, durability, and low maintenance. It handles all critical processes—bottle cleaning, filling, capping, and optional crimping—while supporting multiple filling systems like piston, vacuum, and gear pump fillers, making it adaptable to various product types.

Note: Crimping unit is optional and can be integrated on request. Customization available for bottle sizes and filling methods.

Key Features:

-

Auto-Homing: Automatic alignment and quick setup for efficient operation.

-

Adjustable Speed: Allows fine-tuning of output to match batch size or operator speed.

-

Non-Drip Valve: Ensures spill-free, accurate filling.

-

No Bottle – No Fill – No Seal: Prevents waste and misoperation.

-

Upgradeable Design: Ready for future enhancements and add-ons.

-

Multi-Fill Compatibility: Works with piston fillers, vacuum fillers, and gear pumps.

-

Crimper Integration Available: Add a crimper for complete bottle sealing.

-

Easy Maintenance: Clean design ensures minimal downtime and fast cleaning.

| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 230V AC |

| Brand Name | ANASUYA |

| Model | PF-01 |

| Dimensions | 400mm X 600mm X 650mm |

| Air Pressure Required | 70 PSI |

| Fabrication | SS304 (MS Option Available) |

| Production Speed | 12-13 Bottles Per Minute |

| Weight | 30 Kg |

| Maximum Fill Capacity | 1000 Ml |

Piston Filler – Simple, Efficient & Robust

Model: PF-01 | Make: ANASUYA

Experience effortless and accurate filling with the ANASUYA PF-01 Piston Filler, engineered for precision in handling liquids, creams, gels, and pastes. Designed for small to medium-scale operations, this pneumatically operated unit delivers consistent fills every cycle, offering volume flexibility from 50ml to 1000ml.

Crafted with SS304 stainless steel for hygiene and durability, it is also available in MS fabrication options to suit your budget. Compact, user-friendly, and reliable, the PF-01 is ideal for food, cosmetic, chemical, and pharmaceutical industries.

| Business Type | Manufacturer, Exporter, Supplier |

| Weight | 30 Kgs |

| Voltage | 230V AC |

| Usage | Filling Liquids Into Containers |

| Material | Stainless Steel (SS304) |

| Type | Semi Automatic Servo Filling Machine |

| Brand Name | ANASUYA |

| Dimension | 400mm X 400mm X 650mm |

| Air Pressure | 70 PSI |

| Production Speed | 12-13 BPM |

| Maximum Fill Capacity | 5000 Ml |

SERVO FILLER

Accurate, User-Friendly, and Versatile Liquid Filling

Our Servo Filler is designed to deliver precise and efficient filling for a wide range of liquid products including edible oil, water, juice, dairy, and various chemicals. Engineered with an advanced PLC and HMI interface featuring multiple recipe options, this machine ensures a smooth and user-friendly operation.

With a flexible fill volume range from 50 ml to 5000 ml (5 liters), this servo-based filler is ideal for diverse production requirements. It can operate as a standalone unit or integrate seamlessly with other automatic production equipment for higher efficiency.

Key Features:

-

Wide Fill Range: Easily fills from 50 ml to 5 liters.

-

Precision Control: Servo motor ensures accurate, consistent dosing.

-

Touchscreen HMI: Intuitive operation with recipe memory functionality.

-

Standalone or Inline: Functions independently or with other machines.

-

Low Maintenance: Hygienic SS304 build and minimal wear parts.