Automatic Machine

Leading Manufacturers, Exporters and Wholesaler of Automatic Cup Sealer Machine, Automatic Perfume Bottle Crimping Machine, Automatic Perfume Filling Machine, Automatic Rotary Filling Capping Machine and Automatic Servo Filling Machine from Mumbai.

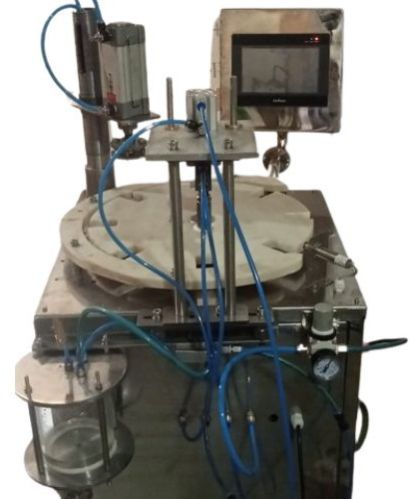

| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 230VAC |

| Usage | High-volume Dairy,Juice,And Ice Cream Cup Filling |

| Material | Stainless Steel (SS304) |

| Type | Automatic Cup Sealer Machine |

| Brand Name | ANASUYA |

| Dimensions | 650mm X 700mm X 1150mm |

| Power | 750 Watts |

| Air Pressure | 75 PSI |

| Production Speed | 12-14 CPM |

| Heater Block | Hollow Brass Heater |

| Weight | 65 KGS |

| Cup Size | DIA 70, 80, 95, Custom Size |

| Maximum Cup Height | 165 |

Product Description

Digital Cup Sealer Automated Efficiency: Our Automatic Cup Sealers

Our Automatic Cup Sealers are the ideal solution for high-volume dairy, juice, and ice cream cup filling. These advanced servo-based machines, complete with an intuitive HMI and PLC, ensure seamless operation and a user-friendly interface. Built with durable SS304 stainless steel, they are designed for longevity and hygiene.

This versatile machine handles the entire process: cup filling, foil placing, foil checking, precise sealing, and automatic cup removal.

For customization and combo unit options, please contact our sales team.

Key Features

-

Auto-homing

Simplifies setup and calibration. -

Speed Adjustment

Customize output to match your production needs. -

Non-drip Valve

Ensures clean and accurate filling. -

Foil Checking

Guarantees every cup is sealed correctly. -

No Cup, No Fill, No Seal

Prevents waste and messy operations. -

Brass Heater

Provides uniform heat distribution for perfect seals. -

Easy to Upgrade

Designed for future enhancements and adaptability. -

Versatile Integration

Compatible with gear pump, piston filler, and gravity filler for different product consistencies. -

Easy to Clean and Maintain

Minimizes downtime and ensures operational efficiency.

Elevate your production capabilities

With a machine that offers precision, reliability, and ease of use, the Digital Cup Sealer is your partner in modern automated packaging.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Pneumatic |

| Condition | New |

| Brand Name | ANASUYA |

| Weight | 14.5 Kg |

| Model | ACM-01 |

| Dimensions | 200mm X 300mm X 450mm |

| Fabrication | SS304 |

| Air Requirement | 75 PSI |

| Production Speed | 12-14 Cycles Per Minute |

| Collet Sizes | 15, 16, 20, 22, 26 Mm |

| Max Bottle Height | 120mm (Customizable) |

Automated Precision for Perfume Manufacturing

Model: ACM-01 | Make: ANASUYA

The Perfume Crimper ACM-01 is a compact, pneumatically operated table-top unit designed for efficient and precise crimping of perfume bottles. Built with SS304 fabrication, it ensures long-term durability and hygiene. Its reliable mechanism delivers consistent sealing across various bottle sizes, supported by interchangeable collets.

This machine features a user-friendly foot switch for hands-free operation and integrates smoothly with existing filling systems like gear pumps, piston fillers, gravity fillers, and vacuum fillers—making it highly adaptable across production lines.

Key Features:

-

Speed Adjustment: Aligns crimping speed with your production flow.

-

Future-Ready Design: Easily upgradable for long-term use.

-

Versatile Integration: Compatible with multiple filling systems.

-

Low Maintenance: Easy to clean, reducing downtime.

| Business Type | Manufacturer, Exporter, Supplier |

| Production Speed | 12-14CPM |

| Air Pressure | 75PSI |

| Voltage | 230VAC |

| Power | 750W |

| Usage | Perfume Filling |

| Material | Stainless Steel (SS304) |

| Color | Silver |

| Type | Automatic Perfume Filling Machine |

| Brand Name | ANASUYA |

| Model | APC-01 |

| Dimension | 650MM X 700MM X 1150MM |

| Weight | 65KGS |

| Cup Size | DIA 70, 80, 95, CUSTOM SIZE |

| Max Cup Height | 120MM |

| Filling Method | Piston Fill, Vacuum Fill, Gear Pump |

Product Description

Automatic Perfume Filler Automated Precision for Perfume Manufacturing

Our Automatic Perfume Fillers are the ultimate solution for high-volume perfume production. These advanced servo-based machines, equipped with an intuitive HMI and PLC, ensure seamless operation and a user-friendly interface. Built with SS304 stainless steel, they are engineered for durability, hygiene, and long-term performance in any production environment.

This versatile machine automates the complete process:

Bottle cleaning, precise filling, secure capping, and reliable crimping—all in one streamlined system. For varying viscosity and filling needs, the system supports Piston, Vacuum, and Dosing Pump fillers.

Key Features

-

Auto-homing

Simplifies setup and calibration for quick, accurate starts. -

Speed Adjustment

Fine-tune output to match your exact production demands. -

Non-drip Valve

Ensures clean, accurate filling and prevents product wastage. -

No Bottle, No Fill, No Seal

Intelligent control system avoids waste and spillage. -

Easy to Upgrade

Built with modularity for future expansion and enhancements. -

Versatile Integration

Compatible with gear pump, piston filler, gravity filler, and vacuum filler. -

Crimper Integration

Supports easy addition of crimping functionality to suit bottle types. -

Easy to Clean and Maintain

Designed for quick maintenance, ensuring minimal downtime and maximum uptime.

Boost Your Production Power

Upgrade your manufacturing line with a machine that offers precision, reliability, flexibility, and unmatched ease of use. The Automatic Perfume Filler is your perfect partner for efficient and hygienic perfume packaging.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | ANASUYA |

| Material | Stainless Steel (SS304) |

| Type | Automatic Rotary Filling And Capping Machine |

| Usage | Filling And Capping Bottles |

| Voltage | 230V AC |

| Weight | 120 Kg |

| Model | RFC-01 |

| Dimensions | 650mm X 700mm X 1400mm |

| Power Consumption | 750 Watts |

| Air Pressure Required | 75 PSI |

| Production Speed | 12-14 Bottles Per Minute (1-head) |

| Bottle Sizes Supported | 200ml, 400ml, 1000ml |

| Max Container Height | 165 Mm |

Rotary Filler and Capper

Model: RFC-01 | Make: ANASUYA

Boost your production efficiency with our Automatic Rotary Filler and Capper, engineered for high-volume operations involving edible oils, sauces, juices, and other liquid products. This advanced servo-based system, equipped with intuitive PLC and HMI controls, ensures precise performance with easy operation. Its robust SS304 stainless steel construction guarantees both hygiene and long-term durability.

Designed with modularity and performance in mind, this rotary system offers effortless integration with various fillers and allows easy customization. For combo units and tailored configurations, please contact our sales team.

Key Features:

-

Auto-Homing: Simplifies setup and automatic positioning.

-

Speed Adjustment: Matches output with your production line requirements.

-

Non-Drip Valve: Prevents spills for clean, accurate filling.

-

No Bottle – No Fill – No Cap: Eliminates waste and enhances safety.

-

Upgrade-Ready: Designed for future enhancements and system expansions.

-

Flexible Integration: Compatible with gear pump, piston, and gravity fillers.

-

Low Maintenance: Easy to clean, reducing downtime and ensuring continuous operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 230V AC |

| Brand Name | ANASUYA |

| Model | SGP-01 |

| Dimensions | 400mm X 400mm X 650mm |

| Air Pressure Required | 70 PSI |

| Fabrication | SS304 Stainless Steel |

| Production Speed | 12-13 Bottles Per Minute |

| Weight | 30 Kg |

| Maximum Fill Capacity | 5000 Ml |

Servo Filler – Accurate & User-Friendly

Model: SGP-01 | Make: ANASUYA

Our Servo Filler SGP-01 is a high-precision liquid filling machine designed for a wide range of applications including edible oil, water, juice, dairy, and chemical products. With integrated PLC and HMI controls, including recipe memory functionality, it delivers consistent performance and easy operation for both standalone and integrated production lines.

Ideal for variable volume requirements, this machine efficiently fills from 50ml up to 5 liters, making it perfect for dynamic production setups.

Key Features:

-

Wide Fill Range: Suitable for volumes from 50ml to 5000ml.

-

Recipe Functionality: Easily switch between product types with saved settings.

-

Integrated PLC & HMI: Simplifies control and enhances usability.

-

Independent or Integrated Use: Can operate as a standalone unit or be connected to other automated machinery.

-

Durable Build: Fabricated with SS304 for hygiene and longevity.

-

Consistent Output: Delivers clean, accurate, and spill-free filling.